What is Marine Growth (or) Bio Fouling ?

Marine Growth (or) Fouling problem arises when barnacles, mussels and other lower forms of marine life as larvae enter in the piping system of the ship and settle on the internal surface where they rapidly grow and multiply.

Effects of Fouling:

- Impairing the heat transfer system.

- Overheating of several water-cooled machineries.

- Increase in the rate of corrosion and thinning of pipes.

- Reduced efficiency which can lead to loss of vessel speed and loss of time.

Antifouling System Description:

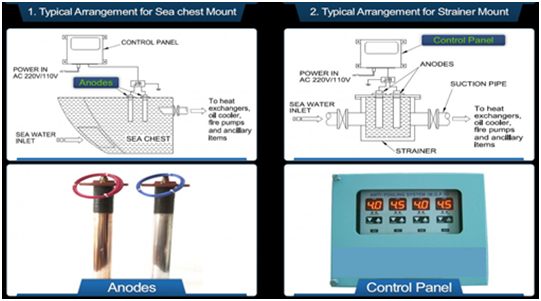

The cathode is formed with an insulated steel frame containing copper and aluminum anodes making use of impressed current system basics. The anode/cathode unit is suspended / placed at the pump inlet so that all the water entering the pump must pass the electrode unit. Dosage levels of copper ions are extremely small and measured in micro grams per liter of seawater. Therefore, relatively small quantities of copper are required to provide protection dependent upon the flow rate and life required.Anti-fouling system consists of two parts “the electrode unit and the control panel. The electrode assembly contains mainly copper anodes. Aluminum Anodes are used in combination with copper in some applications. The actual number and size of the anodes is calculated to suit each installation and available space for mounting the electrode unit. The anodes are connected to the constant current rectifier located within a safe area. For variable pump flow, an intelligent logic is utilized in power supply to provide right dosage of ions.

An effective anti-fouling system enhances the efficiency of marine vessels and offshore structures by preventing bio fouling.

Different time of system includes-

- Conventional Grid Anti Fouling System – has the capability to deliver ions in the open sea at the mouth of the pipe or channel which is at risk of fouling.

- Strainer System – are fairly small units shaped like Strainers and are attached at the mouth of the pipe or pump inlet in the right proportion to set the required ppb level

- Skid Mounted Anti Fouling System – produces the copper ions in a process vessel. The produced treated water is then delivered to the right part of the inlet in the right proportion to set the required ppb level.

All these systems can be prepared with logics to control automatically the production of ions and dispatch of ions depending on the variation in flow rate. The system is intelligent enough to decide the production from minimum to the maximum designed while the flow is zero to the maximum for the pump.

Our Anti-fouling System is designed for our clients with the following features:

- Capable of auto current change (ACC) to 2 or 3 step flow operation

- Touch screen controller is applicable

- Low installation/maintenance costs and Safe

- Environment-friendly with normal 2ppb (parts per billion) dosing rate of copper ion

- Very convenient operation on easy and sophisticated controller

- Data communication and alarm signal can be connected to ship’s AMS

- Simple installation to all kinds of new building as well as retrofitting ships

Benefits of Anti-Fouling System:

- Reduction in power requirements

- Low maintenance system

- No handling or storage of chemicals required

- Environmentally acceptable

- Maintains Plant and Equipment at High Efficiency.

- Reduces Cleaning Cost of Pumps, Pipes, Valves, Sea Chests, and Heat Exchangers etc.

- Increases Life Span of Plant and Equipment’s.

Conventional Grid Anti Fouling System

Skid Mounted Anti fouling System

-

Download : Anti Fouling System

Download : Full Catalogue